JET.TECH Computing

We are a company that does good work and builds good computers that last. What more needs to be said? Let’s put it like this, we are as good at building systems as we are bad at marketing. We are the among the worst at marketing ourselves. We could talk about our previous work, our partnerships, or our experience, but that’s just not a priority for us. You are.

We want to help our customers for life and are invested in making sure our work benefits them.

Jonathan E Trotter- Owner & Operator of JET.TECH Computing and all affiliated brands

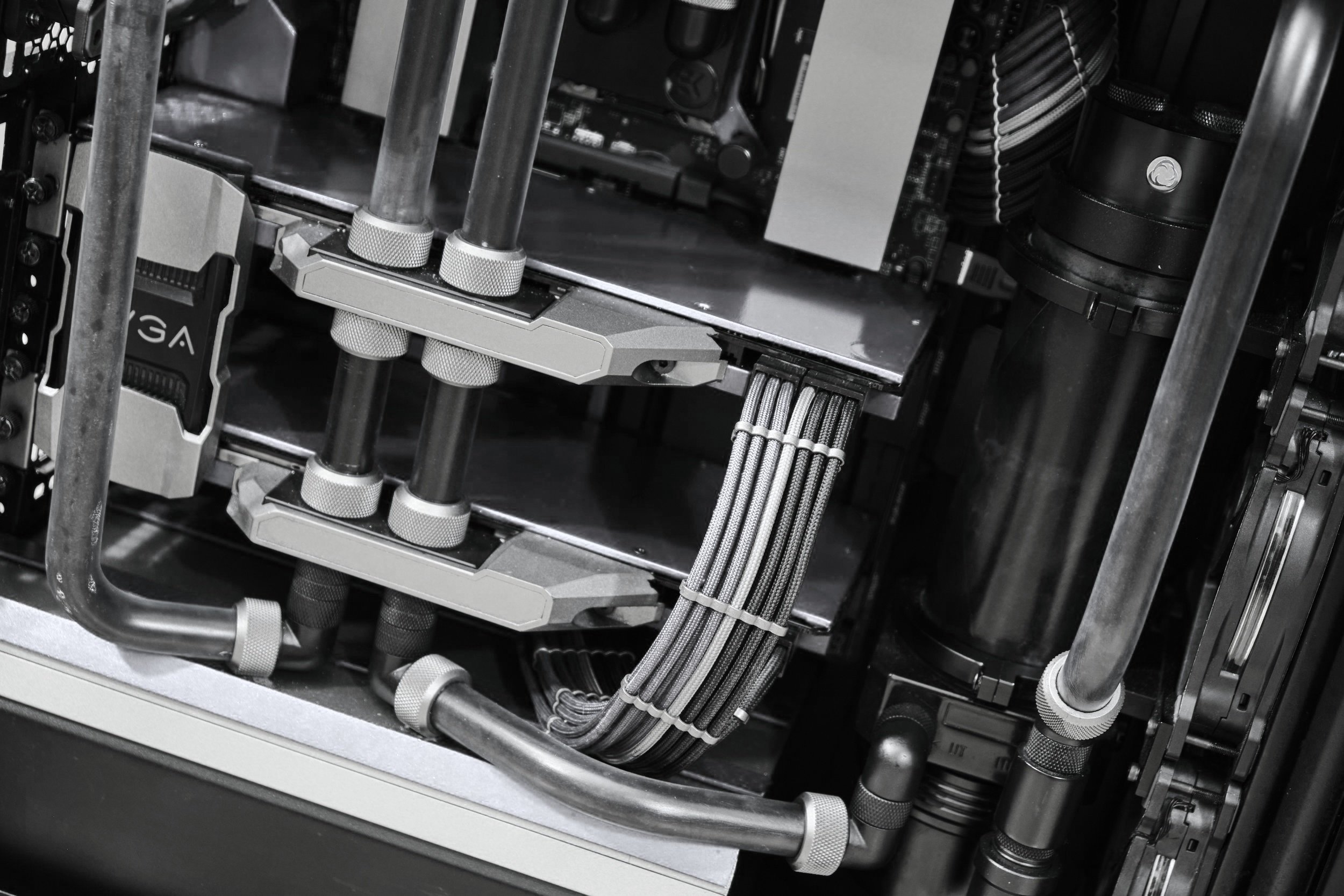

Hey, I’m Jon. I’m the owner of JET.TECH Computing. Where should I start? I guess I will start with the first computer I built for myself with my own money since that is ultimately what started my passion here. It was an Intel I7 2600K, EVGA NVidia GTX 570HD, a 128GB OCZ SSD(Back in my day, these were crazy expensive and you had to walk uphill both ways for miles to the store to buy them), 500GB WD Velociraptor, 16GB of Corsair Vengeance DDR3, and an ASUS P8Z68-V/GEN3 motherboard in a black NZXT Phantom. That was a good system. From there, I started building systems for my friends and family immediately. I gave away so many computers for Christmas, birthdays, because it was Thursday, “you stubbed your toe, here’s a computer”, I was just coming up with reasons. Every bit of money outside of expenses went into it. I just wanted to build, and it was a huge bonus that my family and friends received something unique. I kid you not, I built 53 systems in the first 15 months from that original build. Eventually, I started doing commissions at cost and selling systems and parts online to help partially fund even more systems so I could try more things and test more parts. For a while I was a competitive overclocker and boy, did I spend way too much on CPU pots and LN2. Then, I started to step up to building aesthetically pleasing systems with custom cables, cooling, and paint jobs. Finally, in 2017, I decided to transition from hobbyist to business owner and have never looked back. At first, it was part time. As the business grew, it became apparent I needed to take the leap and go all in. In 2020, after moving 700 miles to Raleigh-Durham, NC, I finally decided to do so. Over the years, as part of the business and as hobbies, I’ve developed significant comparable skill in machining various materials such as metal, plastic, and wood. I’ve also become very experienced in automotive painting, air brushing, ceramic coating and many other finish applications. I know what it takes to optimize thermal design because, well, I’ve directly incrementally tested just about every configuration over the years for custom case fabrication. Hardware validation has become second nature at this point. I’m my companies’ namesake because our reputation, our responsibility to our clientele, and our successes and failures are one and the same. At the end of the day, no matter how big this company grows, I will always be here to get the job done for you.